What is CAD?

Computer-Aided Design (CAD) is the use of computer programs to create two-dimensional drawings or three-dimensional models of physical objects. It includes drawing, drafting, designing and manufacturing of variety of new products and parts.

CAD software is widely used by engineers, designers and architects. It has replaced the traditional “pencil on paper” approach or “manual drafting” method of designing.

CAD deals with creation, modification, analysis and optimization of design. CAD software includes,

I. Computer Aided Design and Drafting (CADD)

II. Computer Aided Engineering (CAE)

III. Computer Aided Manufacturing (CAM)

I. Computer Aided Design and Drafting (CADD)

The process of creating technical drawings or graphical representation for the ease of understanding a concept or an idea using tools like AutoCad, SolidWorks, ProE, Catia etc is known as CADD.

It also includes easiness in modification or recreation in the dimensions (like change in shape and size) of the object.

The Computer Aided Design and Drafting have various capabilities like

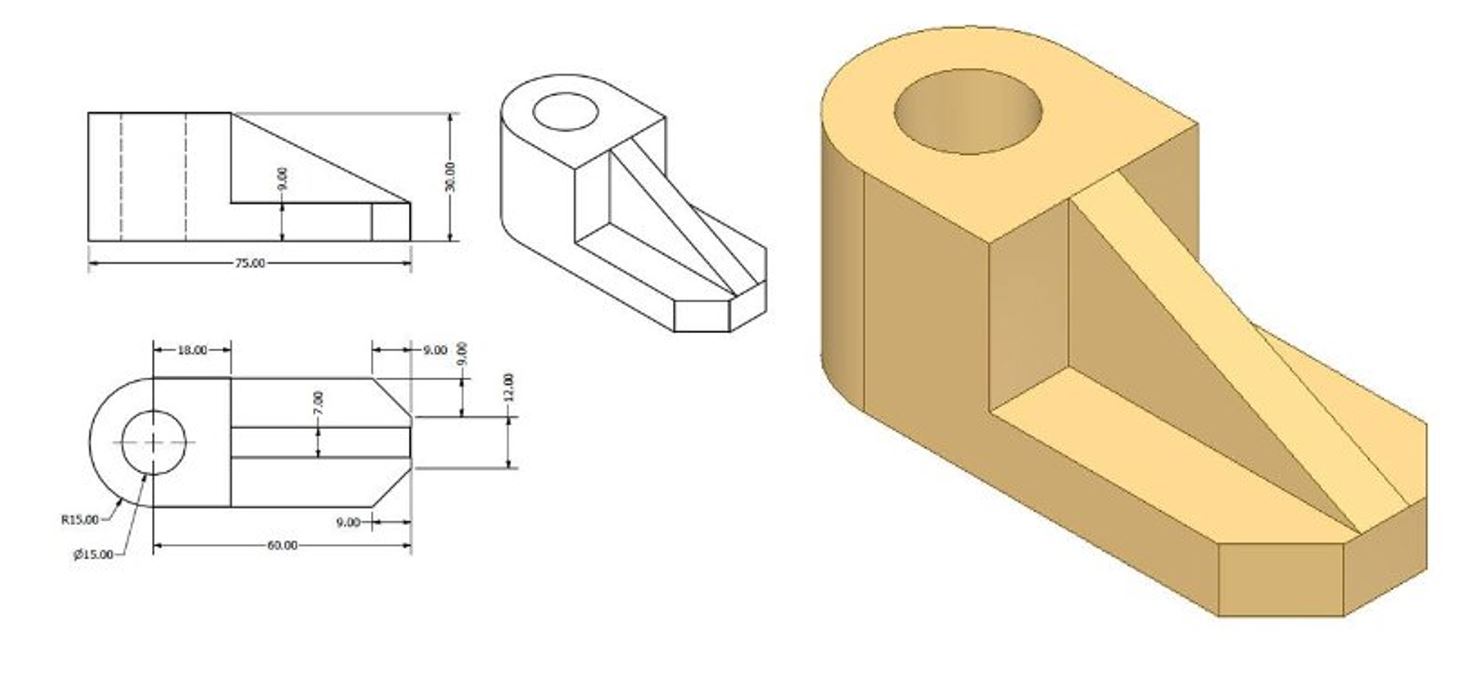

i. 2-D vector based drafting system where points, lines, curves, polygons are used to generate images, design geometries, etc. It is called as as 2-D drafting and detailing.

ii. 3-D surface and solid modelling where in surfaces are generated and then assembled to generate a definite component like a machine tool or engineering structures, etc.

2D drawings into 3D models

3-D Surface and Solid Modelling

Software used for CADD are

- AutoCad

- SolidWorks

- ProE

- Catia, etc.

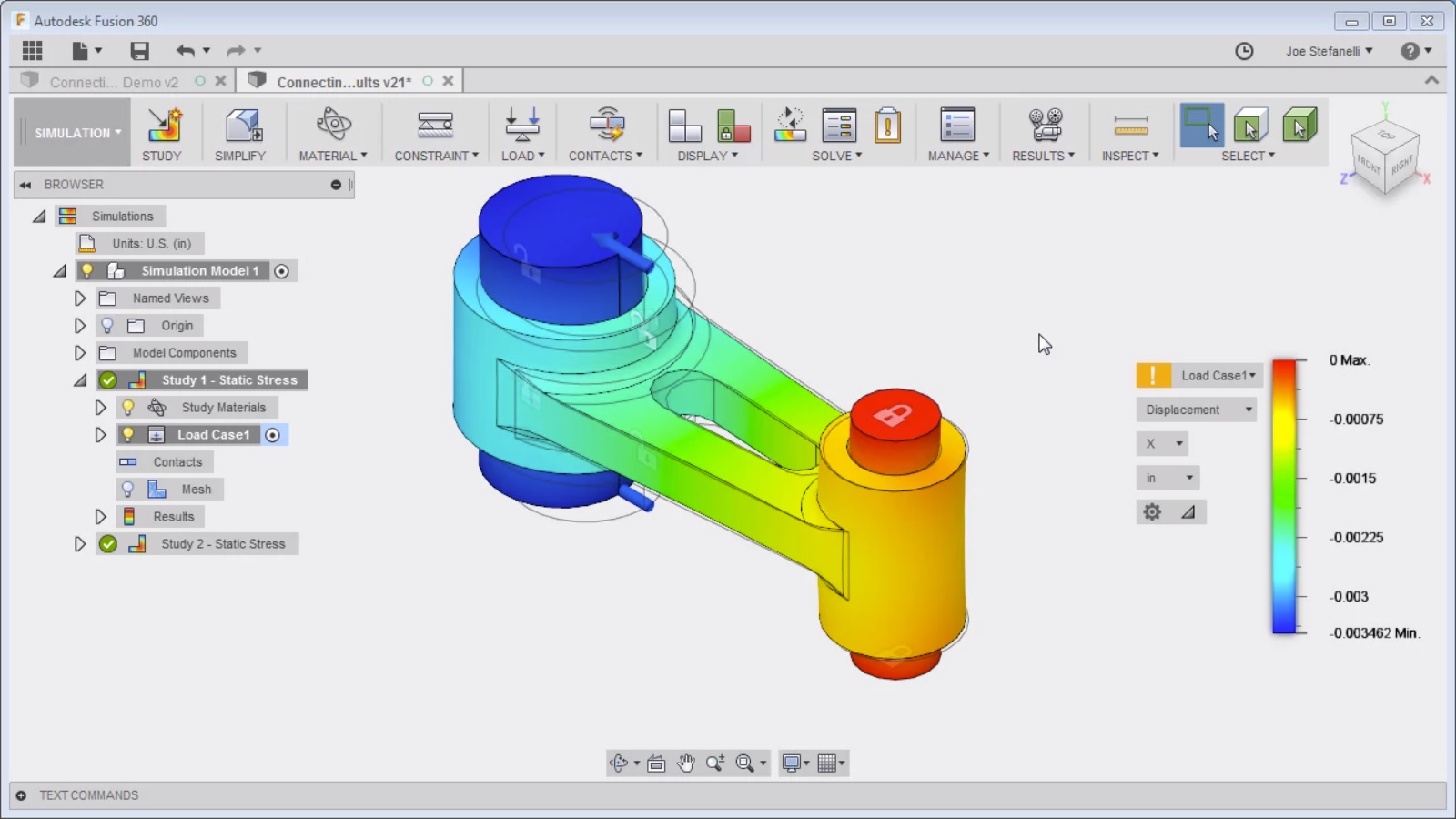

II. Computer Aided Engineering(CAE)

Computer Aided Engineering is used to analyze the performance and durability of components and assembly by simulating, validating and optimization of product.

It figures out what sorts of forces, stress, deformations, and other relevant structural conditions are present in the design as per the analysis conditions specified.

CAE is especially useful because it gives insight of component, whether there is need to modify design or it can be manufactured or where the component might fail.

Software used for CAE are

- Fusion 360

- ANSYS

- Solidworks, etc

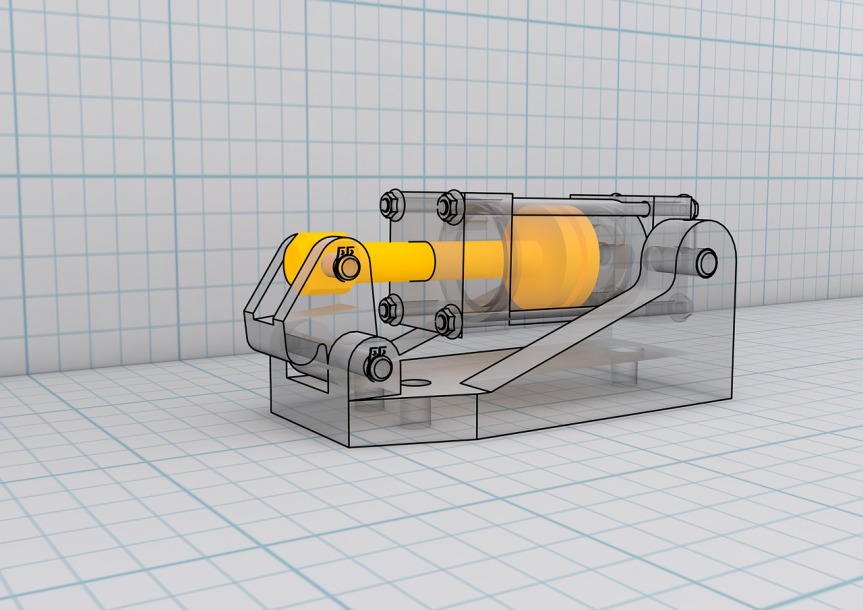

III. Computer Aided Manufacturing (CAM)

Computer Aided Manufacturing (CAM) is numerically controlled program tool where in 2D or 3D models of components are generated using CADD are converted into codes which are used to drive numerically controlled (CNC) machine tools which enable manufacturing of particular component.

In simple words CAM takes CADD geometry and develop the code necessary to manufacture parts on CNC machines.

Software used for CAM are

- Fusion 360

- Autodesk HSM

- MasterCAM, etc

Uses of CAD

- Industrial Designs and Architectural Designs

- Mechanical Design

- Electrical and Electronic Design

- Plant Layout Design

- Product marketing Design

Advantages of CAD

- Increase the Productivity of the Engineer

- Improvement in the Quality of Design

- Improvement in record keeping through better documentation and communication

- Easy visualization of the object in 3D views

- More accurate designs

- Ease of modification

Applications of CAD

- Automotive Industries for building automobile parts, cars, etc.

- Aerospace Industries for building space shuttles, aircrafts, etc.

- In Fashion Designing used by clothing manufacturers to determine the most efficient cut of fabrics.

- Interior Designing for detailed interior digital designs.

Good and easy language for understanding.

LikeLiked by 1 person

Very informative…The way of representing is perfect..Easy to understand…Nice that you tried to cover all topics which i needed.

Hope I get more like this from u. Keep it up

LikeLiked by 1 person

Very well explained and easy to understand.

LikeLiked by 1 person

Simple but effective language……

LikeLike